Leetx Multi-Axis Synchronous Tightening Solution: Enhancing Assembly Precision and Efficiency for Automotive Core Components

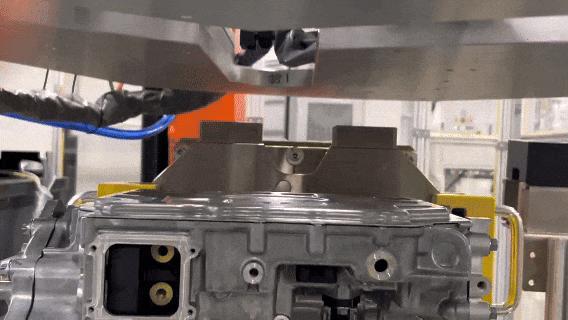

In the automotive manufacturing sector, core components such as engines, transmissions, and electric drives are the "heart" of vehicle performance and quality. The assembly process for these components demands extremely high precision, as even minor deviations can compromise the vehicle's safety and lifespan. For instance, the cylinder head of a drive motor may require the synchronous tightening of over a dozen bolts. Any negligence could lead to insufficient sealing or uneven stress distribution, posing serious safety risks.

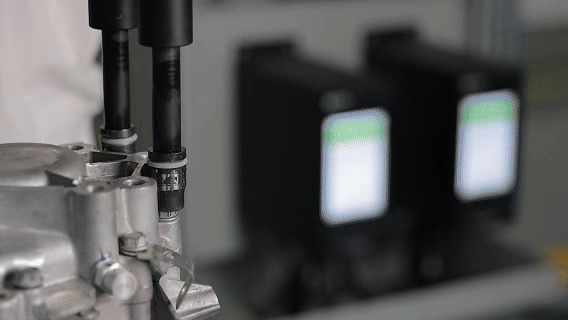

High Torque, Limited Space: Process Challenges Cannot Be IgnoredIn the bolt tightening process for cylinder heads, it's not just about ensuring positional fixation but also incorporating angle strategies to guarantee the scientific nature of the entire assembly process. Meanwhile, these bolts often need to achieve high torque exceeding 100Nm to meet performance requirements.Domestically available tightening axes that can reach this level are generally bulky. In scenarios with small bolt pitches like cylinder heads, large tools struggle to perform multi-axis synchronous operations in confined spaces, undoubtedly increasing process difficulty. Currently, many OEMs still rely on foreign-brand tightening axis tools to address synchronous tightening challenges. While these imported devices offer comprehensive functionality, they are very expensive. Moreover, it's frustrating that users often need to purchase additional licenses or unlock extra permissions to use certain features, which not only adds cost but also reduces flexibility. For enterprises seeking to optimize costs while ensuring process quality, imported solutions are not ideal.Leetx System Solution: More Cost-Effective and Efficient

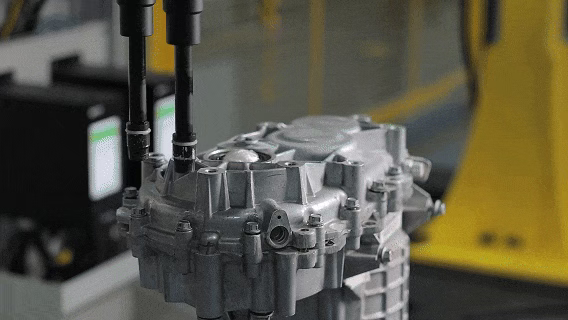

Leetx tightening axis offers customers a more practical and economical choice. This product can support synchronous tightening of over twenty axes, easily handling high-demand stations like drive motor cylinder heads.

Additionally, its internal communication rate is faster, ensuring precise synchronization between multiple axes and more stable process performance. On the operational side, the system setup is simple and intuitive, making it easier for users to get started and reducing additional training and maintenance costs.While safeguarding process quality, Leetx tightening axis genuinely helps customers achieve the dual goals of cost reduction and efficiency improvement, bringing more possibilities to assembly stations and demonstrating the strong competitive edge of domestic equipment.AutoTightening #AutoFeeding #ElectricScrewdriver #SmartElectricScrewdriver #MultiAxisTightening #SynchronousTightening #MultiAxisSync #HighTorque #ElectricDriveTighteningAssembly #EngineTightening #TransmissionTightening #EngineTransmissionAssembly #NewEnergyAssembly

Leetx specializes in the field of intelligent assembly, providing comprehensive solutions for manufacturing processes. Its business covers the entire process of R&D, production, and sales of high-end manufacturing assembly products. Its product portfolio includes tightening systems, automatic screw feeding systems, servo press-fitting systems, etc., widely used in industries such as automotive vehicle manufacturing, automotive components, aviation, 3C electronics, rail transportation, and engineering machinery. With mature solutions in assembly connection technologies like tightening, press-fitting, and screw feeding, Leetx is committed to being a significant force driving the advancement of high-end manufacturing.