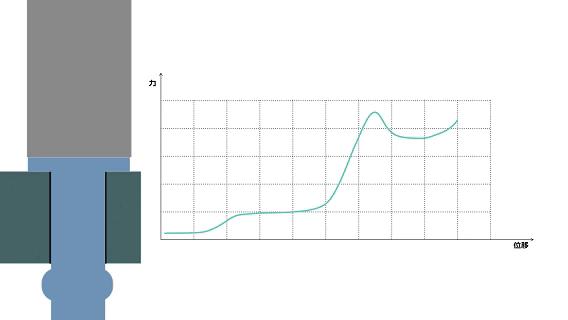

How to Use Envelope Curve Windows to Enhance Press-Fitting Monitoring Effectiveness?In press-fitting processes, the target force value is not always the maximum force encountered during the process. Taking the example of pressing a PIN into a PCB, the special structural design of the PIN can cause a sudden force spike during a specific segment of the insertion, creating a distinct peak. However, this peak value is not necessarily the sole criterion for judging final quality. Relying only on the maximum force value can easily lead to misjudgment .

1 / The "Jumping" Press-Fitting PeaksUpon close observation, the peak force is not constant. Due to inherent tolerances in part manufacturing and assembly, subtle variations exist between different PINs or PCBs. These variations directly cause the peaks in the press-fitting force curve to fluctuate. While this fluctuation is normal, using it as the only standard risks misjudging good parts as defective or, conversely, allowing genuinely faulty parts to pass, ultimately affecting the overall stability of the process .

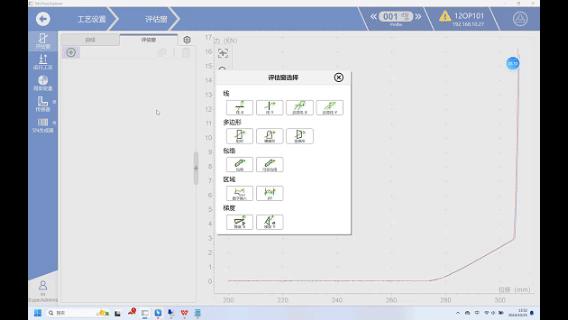

2 / The Solution: The "Envelope Curve Window"To avoid the problems mentioned above, production often employs the "envelope curve window" for process monitoring. The method is straightforward: an upper and lower limit range is set on the force-displacement curve based on product tolerances and design requirements .

If the actual press-fitting curve remains entirely within this "window," the part is judged acceptable.

If any portion of the curve deviates outside the window, it is identified as potentially defective—regardless of how normal the peak or final force values might appear. This allows for a more comprehensive control over the entire press-fitting process .

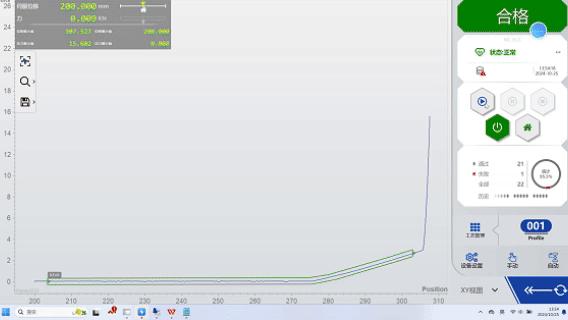

Qualified Effect ↑

Using the envelope curve method, the judgment standard is no longer limited to a single maximum point but covers the entire press-fitting curve. This not only effectively distinguishes between good and defective products but also ensures high consistency across different production batches . In other words, the envelope window acts like a "quality guardrail," permitting normal fluctuations caused by tolerances while promptly intercepting conditions that do not meet process requirements, leading to more stable production and reliable results .ServoPress #PressFitting #Assembly #Press #PressMachine #IGBT #PINPressing #TerminalPressing #PCBAssembly #PinAssembly #AutomotiveElectronicsAssembly #AutomotiveElectronicsPressing #EnvelopeCurve #Envelope

Leetx specializes in the field of intelligent assembly, providing comprehensive solutions for manufacturing processes. Its business covers the entire process of R&D, production, and sales of high-end manufacturing assembly products. Its product portfolio includes fastening systems, automatic screw feeding systems, servo press-fitting systems, etc., widely used in industries such as automotive vehicle manufacturing, automotive components, aviation, 3C electronics, rail transportation, and engineering machinery. With mature solutions in assembly connection technologies like fastening, press-fitting, and screw feeding, Leetx is committed to being a significant force driving the advancement of high-end manufacturing.