How to Effectively Prevent Short Circuits on PCBA Boards?

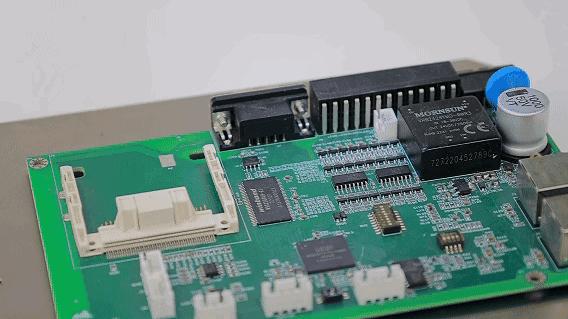

In the new energy electric control industry, as a high-tech sector, the assembly process is crucial to product performance and safety. The assembly must not only meet the precision requirements of technical parameters but also strictly adhere to multiple standards for safety, protection, and environmental compliance. Any minor assembly error, such as screws falling onto the circuit board or dust residue on screw surfaces, can lead to short circuits. Once a PCBA board experiences breakdown or short circuit, it often necessitates replacement of either the new PCBA board or the electric control housing. This results not only in material waste but also impacts production efficiency .

01 Electric Control Assembly Challenges: Minor Flaws, Significant Consequences

Unexpected Screw Dropping: During the fastening process, a single screw that deviates from its intended path and falls onto the PCBA can cause a direct short circuit .

Dust-Attached Screws: Conductive dust (such as metal shavings) adhering to the screw surface or absorbed during the feeding process can also become a short-circuit hazard if the screw detaches .

Foreign Object Residue: Even tiny metal particles or dust can act as potential conductors in high-voltage, high-density circuit environments .

Uncontrolled Screw Count: Failure to effectively monitor the number of screws fastened can lead to loosening due to missing screws, while over-tightening or dropped screws pose greater risks .

Electrostatic Discharge (ESD) Threats: Static electricity generated by operators, tools, or equipment during assembly can easily breakdown precision electronic components on the PCBA. A single undetected ESD event can readily lead to product failure .

02 Three Core Lines of Defense to Mitigate Risks

1.Thorough ESD Protection – Leetx Anti-Static ToolsUsing anti-static tools is the fundamental safeguard. Simultaneously, operators, workbenches, and tools must utilize anti-static products that comply with industry standards to prevent ESD damage .

2."Screw Cleaning" in Automatic Screw Feeding SystemsIntroducing screw cleaners that use vacuum suction technology to remove dust from screw surfaces, avoiding short circuits caused by foreign objects. Traditional screw feeding methods inevitably generate or absorb contaminants like dust and metal shavings during transport. The screw cleaner employs efficient negative pressure nozzles to forcefully remove contaminants from the screw head and threads before precise delivery to the fastening position .

3.Strict Screw Quantity ControlImplementing control measures such as step-by-step guidance, positioning arms, and automatic screw feeding systems to ensure each screw is accurately assembled in place, preventing screws from falling into the product interior .Implementing these measures helps significantly improve assembly quality, reduce economic losses due to errors, and provides strong assurance for the reliability and safety of new energy electric control products .

About Leetx

Leetx specializes in the field of intelligent assembly, providing comprehensive solutions for manufacturing processes. Its business covers the entire process of R&D, production, and sales of high-end manufacturing assembly products. Its product portfolio includes tightening systems, automatic screw feeding systems, servo press-fitting systems, etc., widely used in industries such as automotive vehicle manufacturing, automotive components, aviation, 3C electronics, rail transportation, and engineering machinery. With mature solutions in assembly connection technologies like tightening, press-fitting, and screw feeding, Leetx is committed to being a significant force driving the advancement of high-end manufacturing .