How to Address Precision Challenges in Bore Machining?

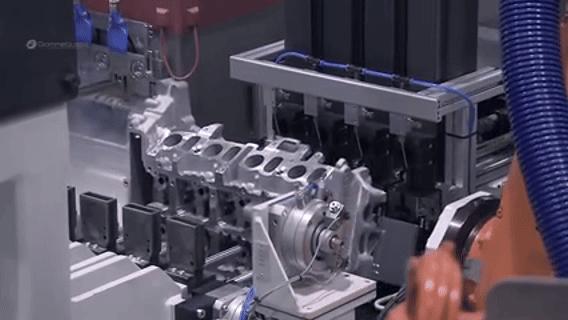

In the complex assembly process of automotive engines, the press-fit quality of key components such as valve guides and valve seat rings directly impacts the engine's sealing performance, durability, and overall performance. These components utilize interference fits, relying on precise control of the interference amount to ensure bonding strength and sealing effectiveness. However, bore machining has always been a challenge for the industry due to its extremely high precision requirements .01 Bore Diameter Error: The Invisible "Killer" of Press-Fit Qualification RateDuring precision bore machining, factors such as tool wear, machine tool thermal deformation, or changes in material properties can lead to minute deviations in the bore diameter. For components like engine guides and seat rings, which demand extremely high precision for interference fits, such deviations can easily cause serious assembly hidden risks. Once assembly quality issues arise, it can lead to major defects such as sealing failure, abnormal noise, oil leakage, or even loss of function .

Oversized Aperture: If the bore diameter is too small, excessive friction can cause the press head to stop prematurely, preventing the component from reaching its set position and failing to achieve an effective interference fit .

Undersized Aperture: If the bore diameter is too large, force-controlled press-fitting may not reach the proper position, while position-controlled press-fitting can lead to over-pressing and deformation. In extreme cases, this may cause the seat ring to deform or crack .

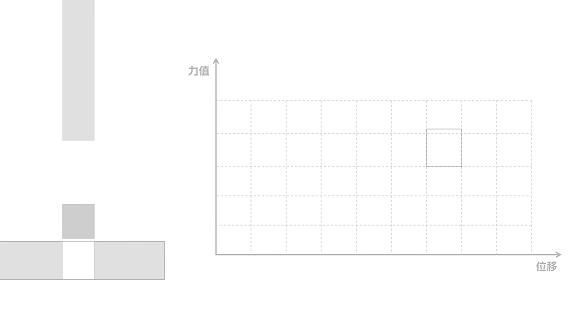

02 Step Compensation Strategy: Precisely Balancing Position and Force

Faced with the challenge of assembly accuracy due to bore diameter fluctuations, traditional press-fitting equipment is often inadequate. Modern servo presses, based on global variable position compensation strategies, can simultaneously meet the dual requirements of "target position" and "target force value" .

Target Position Press-Fitting: The servo press first performs press-fitting according to the set "target position," ensuring the component reaches the installation depth. The system accurately records the actual pressing force value at this moment in real-time .

Position Compensation Press-Fitting Based on Measured Force: The system calculates the required compensation displacement based on the set force range and compensation coefficient. The servo press then executes compensation press-fitting, applying a minute, controlled additional displacement on top of the theoretical position to precisely supplement the force value .

The ingenuity of the step compensation strategy lies in its clever combination of the advantages of position control and force control. Even when bore diameter fluctuations result in the position being met but the force being insufficient, intelligent position compensation can accurately bring the force value within the target range through a minimal additional displacement, achieving dual assurance for the interference fit. This strategy provides a solid process foundation for high-precision, high-reliability assembly of engine guides and seat rings .

About Leetx

Leetx specializes in the field of intelligent assembly, providing comprehensive solutions for manufacturing processes. Its business covers the entire process of R&D, production, and sales of high-end manufacturing assembly products. Its product portfolio includes tightening systems, automatic screw feeding systems, servo press-fitting systems, etc., widely used in industries such as automotive vehicle manufacturing, automotive components, aviation, 3C electronics, rail transportation, and engineering machinery. With mature solutions in assembly connection technologies like tightening, press-fitting, and screw feeding, Leetx is committed to being a significant force driving the advancement of high-end manufacturing .